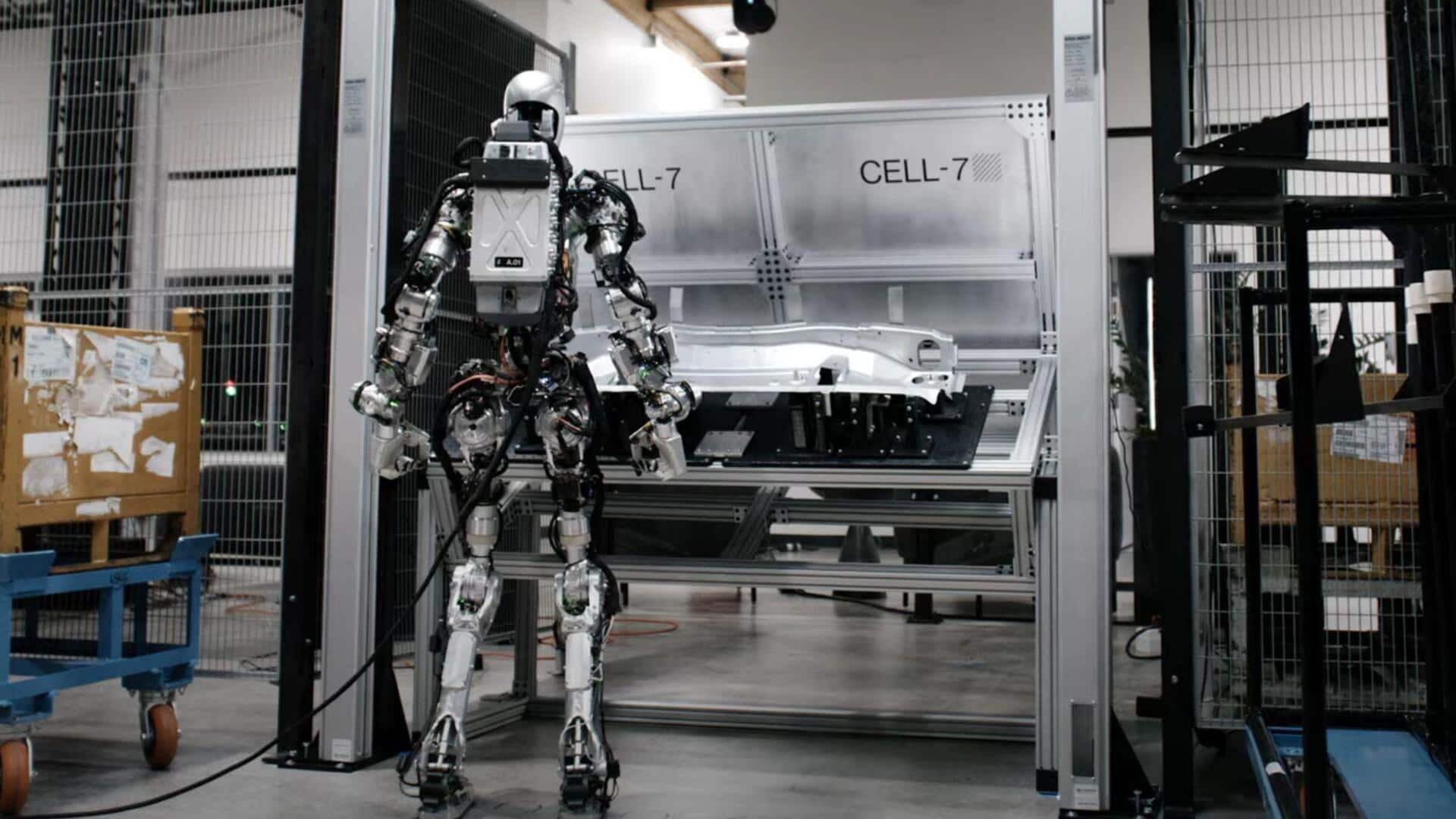

California-based robotics firm, Figure, has released a video demonstrating its humanoid robot, Figure 01, participating in the car assembly process at BMW’s facility in Spartanburg, South Carolina.The video highlighted the robot’s ability to perform all tasks autonomously using neural networks, that map pixels directly to actions.Another clip demonstrating Figure 01 brewing coffee post a 10-hour training session was also put out.

Figure 01: A versatile addition to BMW’s production line

Figure 01 is designed to execute a variety of manufacturing jobs including handling sheet metal, operating in the body shop, and managing the warehouse.The fully electric robot stands 1.6m tall and weighs 60kg with a payload capacity of 19.96kg. It can operate for five hours on a single charge.Upon deployment in January, Figure announced that the robots would undergo training for twelve to twenty-four months, before being integrated into the facility with precise skills required for each task.

Carmakers testing human-like robots for years

Several automakers are exploring humanoid robots for production.Besides BMW, firms such as Mercedes-Benz, Honda, and Hyundai have been testing human-like robots for years to automate tasks on assembly lines.Figure’s video demonstration follows the company’s first commercial agreement with BMW in January 2024, to deploy its fully autonomous robot on the German carmaker’s production line.

Figure’s rapid advancements and future prospects

Founded by Brett Adcock in 2022, Figure has made significant strides due to a talented team of ex-employees from tech giants like Boston Dynamics, Tesla, Archer Aviation, and Google’s DeepMind.Figure 01 swiftly transitioned from concept to reality, demonstrating basic autonomous functions by mid-2023.By the end of the year, its adaptive learning abilities were refined and it was set for integration into BMW’s workforce by mid-January.

OpenAI’s vision-language model powers the robot

The humanoid robot’s abilities are fueled by a vision-language model from OpenAI, which processes data from Figure 01’s cameras.The robot’s neural networks process images at a rate of 10Hz via its cameras, and produce actions with 24-degree of freedom at 200Hz.According to Figure, AI systems ensure accurate placement of sheet metal within tolerances tighter than 1cm, and navigation is accomplished solely through simulated object training.

Addressing workforce challenges with automation

Figure aims to create a global model that can manage billion-unit humanoid robots, as it identifies about 10 million unsafe/undesirable jobs in the US alone.The company believes an aging population will exacerbate workforce scaling problems, leading to a stagnant labor supply rise this century.To counter this, Figure suggests that increased productivity through more automation is required.

Read More-Meta AI can now reply to photos on WhatsApp